Epoxy flooring has gained widespread popularity in recent years, becoming a preferred choice for both commercial and residential spaces. Its appeal lies not only in its sleek appearance and versatility but also in its remarkable strength and durability. These characteristics make it an ideal flooring solution for environments that demand resilience and long-lasting performance. However, what exactly gives epoxy flooring its exceptional durability? The answer lies in the science behind its chemical composition and curing process. This article delves into the scientific principles that underpin epoxy flooring’s strength and longevity, exploring why it outperforms many traditional flooring materials.

Overview of Epoxy Flooring’s Popularity

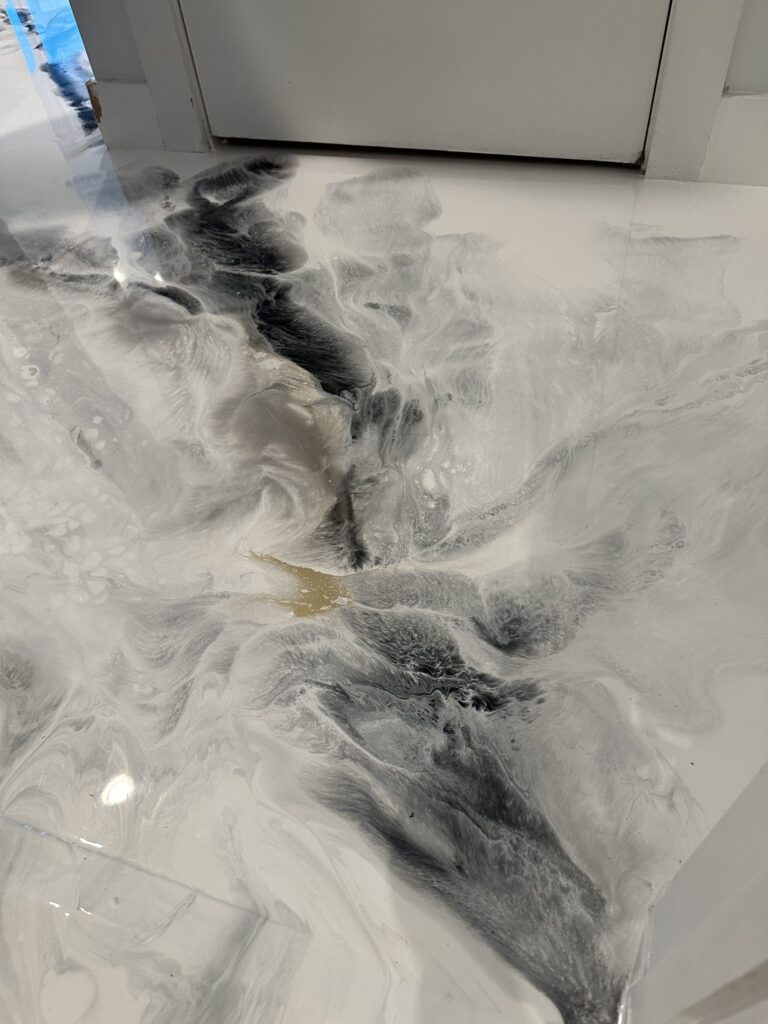

Epoxy flooring is known for its seamless finish, resistance to damage, and ability to withstand heavy traffic and harsh conditions. It has become increasingly popular in settings such as industrial warehouses, commercial kitchens, garages, and even residential living spaces due to its aesthetic flexibility and robust performance. But beyond these surface-level attributes, there is a sophisticated science that accounts for the superior performance of epoxy flooring. Understanding this science is key to appreciating why epoxy flooring is such a reliable and enduring choice.

Focus on the Science Behind Its Strength and Durability

The strength and longevity of epoxy flooring are rooted in its unique chemical properties. Epoxy is not just a single substance; it is a composite material made from a specific blend of chemicals that undergoes a transformation during the installation process. This transformation, known as curing, is where the science of epoxy truly shines, turning a liquid mixture into a hard, durable surface that can withstand an impressive range of environmental stresses.

Chemical Composition

Explanation of Epoxy Resin and Hardener

At the core of epoxy flooring are two primary components: epoxy resin and hardener. The epoxy resin is a liquid polymer that, when mixed with the hardener—a reactive agent—begins a chemical reaction known as polymerization. This reaction results in the formation of a highly cross-linked polymer structure. This structure is what gives epoxy its renowned strength and durability.

The resin component typically contains bisphenol A or bisphenol F, which contributes to the thermal stability and chemical resistance of the final product. The hardener, often composed of amines, reacts with the resin to initiate the curing process. Together, these components create a robust, cohesive matrix that is both incredibly strong and resistant to a variety of chemical and physical stressors.

The Curing Process and Its Impact on Strength

The curing process is fundamental to the performance of epoxy flooring. When the epoxy resin and hardener are mixed, they undergo an exothermic reaction, releasing heat as the mixture transitions from a liquid to a solid state. This reaction forms a tightly bonded, three-dimensional network of molecules, which gives the epoxy its remarkable hardness and resistance to impact.

The rate and conditions of curing can significantly affect the final properties of the epoxy. For instance, a slow, controlled cure at optimal temperatures allows for more extensive cross-linking, resulting in a harder and more durable surface. Conversely, an improper or rushed curing process can lead to incomplete bonding, reducing the strength and longevity of the floor. This precise control over the curing process is one reason why professionally installed epoxy flooring tends to outperform do-it-yourself applications.

Factors Contributing to Longevity

Resistance to Wear and Abrasion

One of the standout qualities of epoxy flooring is its exceptional resistance to wear and abrasion. The dense, cross-linked molecular structure formed during curing creates a surface that can withstand significant mechanical stress without showing signs of damage. This makes epoxy an ideal choice for high-traffic areas, such as warehouses, retail environments, and garages, where the flooring is subjected to continuous use and heavy loads.

Moreover, epoxy’s hardness protects against scratches and scuffs that can mar other types of flooring, such as wood or vinyl. Even under the constant movement of heavy machinery or the repetitive impact of dropped tools, epoxy flooring maintains its integrity, demonstrating its superior wear resistance over time.

Chemical and Heat Resistance

In addition to its mechanical strength, epoxy flooring is highly resistant to a wide range of chemicals, including oils, solvents, and acids. This chemical resistance is particularly valuable in industrial and commercial settings, where floors are frequently exposed to potentially damaging substances. The cross-linked polymer network prevents these chemicals from penetrating the surface, reducing the risk of stains, degradation, or corrosion.

Epoxy flooring also offers excellent heat resistance, which is crucial in environments exposed to high temperatures. The thermal stability of epoxy is due to its strong molecular bonds, which remain intact even under extreme conditions. This resistance to heat and chemicals further enhances the longevity of epoxy floors, making them a reliable choice for a diverse range of applications.

Comparison with Other Flooring Materials

Durability Comparisons with Vinyl, Tile, and Concrete

When compared to other popular flooring materials, epoxy stands out for its durability. Vinyl, while affordable and easy to install, lacks the strength and chemical resistance of epoxy and can be prone to tearing, scratching, and discoloration over time. Tile, although durable and resistant to stains, can crack under heavy impact and requires regular maintenance of grout lines, which can harbor dirt and bacteria.

Concrete is often considered a durable flooring option, especially in industrial settings. However, untreated concrete is porous and susceptible to cracking, staining, and moisture damage. Epoxy flooring, when applied over concrete, not only seals and protects the underlying material but also enhances its durability by providing a hard, impermeable surface that resists wear, chemicals, and moisture.

Longevity in Different Environments (Commercial vs. Residential)

The longevity of epoxy flooring is influenced by the environment in which it is installed. In commercial settings, where floors are subjected to heavy machinery, foot traffic, and exposure to chemicals, epoxy flooring provides a durable solution that can last for decades with minimal maintenance. In residential settings, epoxy’s longevity is even more pronounced. It offers a low-maintenance, durable surface that can withstand the rigors of everyday life, from spills and dropped objects to pet claws and frequent cleaning.

The versatility of epoxy flooring makes it suitable for both commercial and residential environments, offering a long-lasting solution that minimizes the need for repairs and replacements, thereby reducing costs over the floor’s lifespan.

Case Studies and Research

Studies on Epoxy Floor Performance Over Time

Numerous studies have examined the performance of epoxy flooring over time, highlighting its superior durability and longevity. For example, research has shown that epoxy coatings can maintain their structural integrity and aesthetic appeal even after years of heavy use. These studies often compare epoxy with other flooring materials, consistently demonstrating its ability to resist wear, chemicals, and environmental factors better than most alternatives.

One study, in particular, focused on the use of epoxy flooring in industrial environments and found that floors coated with epoxy exhibited significantly lower levels of wear and tear compared to untreated concrete or vinyl. The study concluded that epoxy flooring is a cost-effective choice for environments requiring high durability and minimal maintenance.

Real-Life Examples of Long-Lasting Installations

Real-life examples further underscore the durability of epoxy flooring. In a manufacturing plant, for instance, epoxy floors installed over a decade ago continue to perform exceptionally well, withstanding the constant movement of forklifts, heavy equipment, and exposure to various chemicals. In a residential garage, homeowners have reported that their epoxy-coated floors have remained in pristine condition for over 15 years, despite frequent vehicle use and exposure to harsh cleaning agents.

These real-world examples demonstrate that, when installed correctly and maintained properly, epoxy flooring can offer decades of reliable service, making it an excellent long-term investment.

The science behind epoxy flooring’s strength and longevity lies in its unique chemical composition and the rigorous curing process that transforms it into a robust, resilient surface. Its superior resistance to wear, chemicals, and heat, coupled with its low maintenance requirements, make it an ideal flooring solution for a wide range of environments, from industrial warehouses to modern homes.

By understanding the scientific principles that contribute to epoxy flooring’s exceptional performance, property owners can make an informed decision that ensures durability and cost-effectiveness over time. For those seeking a flooring option that combines strength, longevity, and versatility, epoxy flooring stands out as a compelling choice that offers significant benefits long into the future.